ML-S Flatbed die cutter machine

- Suitable materials: Paper and paperboard, Corrugated board, Sticky label (kiss cut) Plastic sheets, eg. PVC, PP sheets (Heating plate)

It is used for die cutting and creasing various types of paper, paperboard, corrugated board, label and plastic sheets, with functions of single pressing & cutting, continuous pressing & cutting with or without an adjustable time-delay during the continuation. The operation system is well-designed and easy to use, and the clamp for pressing can be opened at a wide angle.

| Model | Inner Chase Size(mm) | Speed

(strokes/min) |

Max.Rule Length(m) | Motor Power(kw) | Weight(t) | Overall Dimensions(mm) |

| ML-750S | 750*520 | 26±2 | <15 | 2.2kw | 1.8 | 1450×1400×1400 |

| ML-930S | 930*670 | 23±2 | <25 | 4kw | 2.7 | 1550×1900×1650 |

| ML-1040S | 1040*720 | 23±2 | <30 | 4kw | 3 | 1650×1900×1650 |

| ML-1100S | 1100*800 | 20±2 | <32 | 4kw | 3.7 | 1800×2000×1800 |

| ML-1200S | 1200*820 | 20±2 | <35 | 4kw | 4.2 | 1900×2000×1800 |

| ML-1300S | 1300*920 | 16±2 | <40 | 5.5kw | 5.3 | 2100×2000×2000 |

| ML-1400S | 1400*1000 | 15±2 | <45 | 5.5kw | 6 | 2200×2000×2000 |

| ML-1500S | 1500*1050 | 14±2 | <48 | 5.5kw | 6.2 | 2300×2000×2000 |

| ML-1600 | 1600*1250 | 13±2 | <50 | 11kw | 10.5 | 2800×2300×2400 |

| ML-1800 | 1800*1300 | 13±2 | <60 | 11kw | 11.5 | 3000×2300×2500 |

| ML-2000 | 2000*1400 | 13±2 | <65 | 15kw | 14 | 3200×2400×2600 |

| ML-2200 | 2200*1400 | 13±2 | <70 | 15kw | 15 | 3400×2400×2600 |

| ML-2500 | 2500*1400 | 11±3 | <80 | 22kw | 16 | 3700×2400×2600 |

| ML-2800 | 2800×1600 | 11±3 | <85 | 30kw | 18 | 4000×2400×2600 |

| ML-3000 | 3000×1600 | 11±3 | <90 | 30kw | 20 | 4200×2400×2600 |

Usage:

ML-930-1040-1100-1200 manual vertical die cutting machine is used for die cutting and creasing various paper, paperboard, corrugated board, plastic sheet (like PVC, PP), with functions of single pressing & cutting, continuous pressing & cutting and open time-delay, time delay range is adjustable.

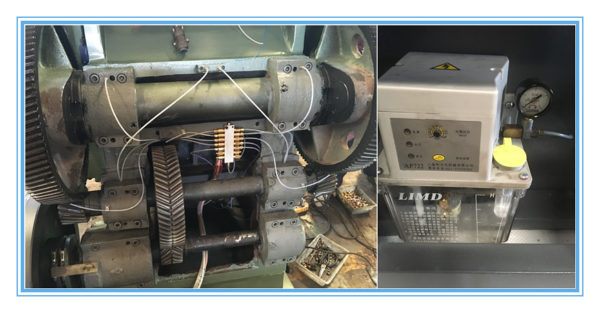

It is equipped with central lubrication system and automatic oil pump. The body of machine is made of high strength casting iron. The torque of flywheel is big with higher force of press.

According to the customer’s different requirements, it can be equipped with infrared control device, CE safety guard device, heating plate (for die cutting plastic sheet), pneumatic clutch or frequency convertor (speed adjustment).

Machine body -High Strength casting iron. ensure machine stable running in large pressure

Automatic Oil Pump – it’s more convenient to maintain the machine

Control panel -three running mode for your choice. single pressing & cutting, continuous pressing & cutting and open time-delay

Get In Touch

Contact person: Tom Miao

Phone/Whatsapp/Wechat: +86-13587585227

Email: fengfe@acutmachine.com

If you want to get a quotation, pls fill here